Hidden Technologies of Snowboards

(Image provided by Lobster Snowboards)

https://www.reddit.com/r/Steep/comments/ayvx0i/loving_the_new_lobster_boards/

Introduction

A snowboard is a specialized piece of equipment designed maneuver through snow. It enables riders to incorporate various mobility styles and even perform tricks down the slopes. The winter sport of snowboarding seemingly merges aspects of surfing, skateboarding, and skiing, some of which are reflected into the technology of a snowboard. This description will cover the common materials used in production, key features, and profiles that make modern snowboards highly efficient and part of an entertaining hobby for millions of riders.

Materials

Modern snowboards are crafted using a combination of materials to achieve an optimal balance of strength, flexibility, and weight. The core of a snowboard is typically constructed from wood, such as poplar or bamboo, which provides a lightweight yet durable foundation. This core is often reinforced with layers of fiberglass, carbon fiber, or aluminum in varied proportions to enhance the board's strength and responsiveness. This is important for overall use but is put to the test in certain areas of the ski slope like the terrain park. Here the board may contact rails, tubes, or jumps that can apply high stress in awkward ways to the board. Epoxy is a crucial addition to the chemistry of the board, as it helps to properly bond everything together.

Construction

There are three main steps in the construction of a snowboard: layup, curing, and finishing.

Layup

Boards are crafted layer-by-layer, typically starting at the bottom or the base of the snowboard. By alternating layers of P-tex, fiberglass, epoxy, wood, and aluminum, performance goals can be modified to accommodate for a rider who may be seeking speed rather than springiness when purchasing a board.

Curing

Snowboards are clamped using a flexible piece of aluminum, holding the layers together, and cured under variable conditions. During curing, pressure, heat, and time solidify the board into its unified form; however, they still would not be identifiable.

Finishing

Finishing gives snowboards their identity to which they would be recognized by many. In finishing, they are trimmed to remove any excess materials. They are shaped to their desired dimensions and proportions (Figure 1). Their base is sanded by both machine and man to ensure a smooth, consistent finish and then it is buffed using a wheel or belt. A wax is applied to this base and its edges are sharpened to enhance control across changing conditions.

Figure 1: A snowboard in the process of being shaped by a trained technician.

(Image provided by Burton)

Key Features

Figure 2: A snowboard in the process of being shaped by a trained technician.

Figure 3: Differing binding set up designs. Difference in designs allow for more precise stance adjustments.

https://s2as.com/en-us/blogs/buying-guides/buyers-guide-snowboard-bindings

Figure 4: Magne-traction technology boards benefit from the waving edge used in design.

The key features are the unified “tools” of the snowboard that read the riders’ movements and translate them to control on the snow. They are the base, the bindings and mounting systems, and the edges and sidewalls.

The Base

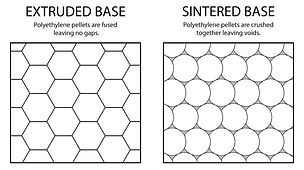

The base of a snowboard is the bottom layer that makes direct contact with the snow and is therefore crucial for performance. Most snowboards feature a high-density polyethylene (P-Tex) base, known for its durability and wax retention. The P-Tex material of the base and the wax within it help to reduce friction and increase speed. There are two main types of bases: extruded and sintered (Figure 2). Extruded bases are easier to repair and maintain, while sintered bases offer better performance and speed due to their porous structure that absorbs more wax.

Bindings and Mounting Systems

For a rider to properly operate a snowboard, a pair of bindings are required. Bindings lock the rider's boots to the top of the snowboard using a pair of latches for each foot: one around toes and another around the ankle. Modern bindings are designed to be lightweight, adjustable, and comfortable, with features like highbacks for support and cushioning for shock absorption. Snowboards come with different mounting systems, such as the traditional 4x4 pattern, the channel system, 3D, or 2x4 (Figure 3).

Edges and Sidewalls

The edges of a snowboard are made from metal and are designed to provide grip and control in icy conditions or on hard-packed snow. Innovation to edge designs, such as serrated edges or magne-traction, enhance edge hold by increasing the contact points with the snow (Figure 4). The sidewalls make up the majority of the snowboard’s side and are typically made from durable materials like ABS plastic. Their purpose is to protect the core and edges from deformation in impacts.

Profiles

The overall topography can vary between boards and the difference can be seen when viewed at a side angle. For example, traditional camber boards are slightly arched in the middle, providing excellent edge control and stability at high speeds by exerting pressure at the nose and tail of the board (Figure 5). Rocker boards, on the other hand, have a reverse camber, with the center of the board touching the snow and the nose and tail slightly raised. This design is ideal for powdery snow and freestyle riding as it offers better floatation and maneuverability. Many modern snowboards feature hybrid profiles that combine elements of both camber and rocker, providing a versatile riding experience.

Figure 5: Varied board topography provides modifiable control.

Conclusion

Snowboards represent a pinnacle of modern engineering and are continuously being improved upon and modified to heighten the sport even further. They utilize advanced materials, innovative designs, old-school feedback to elevate the riding experience. Riders, whether new to the sport or seasoned professionals, all benefit from understanding the features and technologies of snowboards. This knowledge can prove extremely beneficial when selecting the right board for to fit one’s needs and enhancing their performance on the slopes.

References

Encyclopædia Britannica, inc. (2025, March 7). Snowboarding. Encyclopædia

Britannica. https://www.britannica.com/sports/snowboarding

How is a snowboard made?. Burton. (n.d.).

https://www.burton.com/discover/s/article/how-is-a-

snowboard-made#:~:text=When%20building%20a%20snowboard%2C%20we,press%20until%20everything%20is%20cured.

The impact of technology on snowboarding. TheSportsReviewer.com. (2024,

February 17). https://thesportsreviewer.com/the-impact-of-technology-on-snowboarding/

Koons, W. (2023, May 9). How snowboarding has changed in the last 10-15 years.

Lyons, M. (2021, August 26). Snowboard features explained. Rome US.

https://romesnowboards.com/blogs/news/snowboard-features-explained

REI. (n.d.). How to choose a snowboard: Rei Co-op. REI.

https://www.rei.com/learn/expert-advice/snowboard.html

Stokes, V. (2021, February 23). How technology is changing snowboarding | teton

gravity research. Teton Gravity Research. https://www.tetongravity.com/story/snowboard/how-technology-is-changing-snowboarding